Eliminate Dust from Your Precision Die Mold TRINC's Non-Blow-Ionizing technology improves product precision by eliminating dust from die molds without using blowers or compressed air. Their static eliminator, based on the "Ion Engine method," emits ions with positive and negative polarities, propelled by Coulomb's repulsive force. This ion-based method effectively neutralizes and repels dust particles, ensuring a cleaner manufacturing process.

Ionizers TRINC

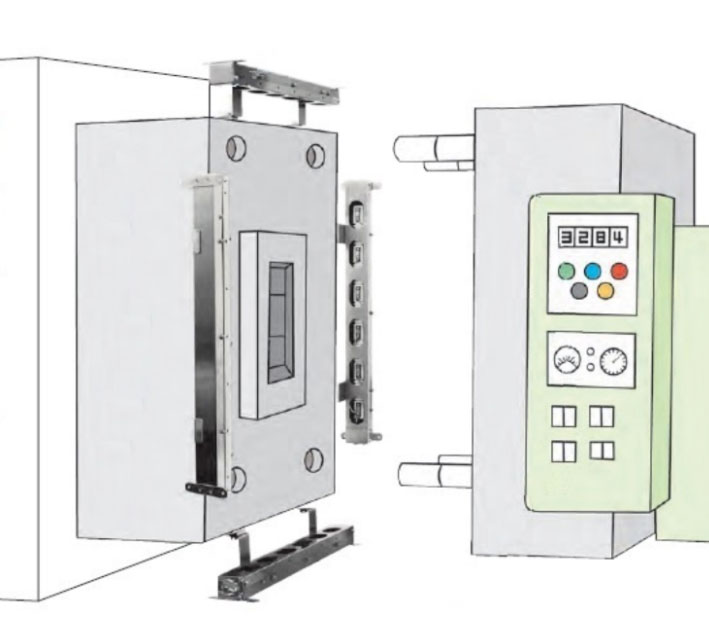

MOLD TRINC for Resin Mold Operation

Specialized Static Eliminator with heat-resistant for Resin Molding: No-Blow Ionizing and Powerful Static Elimination.

Features

- Reduce the fraction of defective products caused by foreign materials. Prevent dust adherence to molded articles, gate flakes, and burrs to improve product quality.

- Prevent molding dies from fracturing. Ensure safe extraction of molded articles from the dies, preventing accidents and die fracturing.

- Enable unattended operation and cost reduction. Preventing die fractures reduces product delivery time, leading to cost savings.

- No-Blow TRINC solves die-cooling-off and dust rising problems. Unlike conventional ionizers using air, MOLD TRINC provides stable product quality by eliminating temperature fluctuations and dust raised by air.

- Easily exchange dies with magnet-mounting. MOLD TRINC uses magnet-mounting for light-weight ion-bars, streamlining the die exchange, repairs, and maintenance process.

- Ions emitted without air assistance just before die opening. An energy-saving system ensures ions emanate only during die opening, reducing maintenance work and ozone generation for an environmentally conscious model.

PELLETRINC for Vacuum Transport

TAS-286 PEL

A perfect solution to static problems of pellets inside the molding machines. The specialized static eliminator prevents resin pellet adhesion to the hopper, color unevenness in molding, and electric shock from the hose while ensuring a steady resin pellet supply.

Features

- Prevents pellets from attaching to the hopper inner wall.

- Eliminates errors in the empty-hopper detector.

- Avoids color shading on resin moldings.

- Prevents electric shock resulting from inadvertent touch to the pellet suction hoses.

- Requires no additional air or setting work.

- It can be easily installed in various sizes of houses.

Metal Mold Cleaner

TAS-1332 MMC-HT160-DC (w/ dust collector)

TAS-1333 MMC-HT160 (w/o dust collector)

Features

- High dust removal rate.

- Equipped with an ionizer.

- Does not disturb temperature control.

- Heat-resistant head.

- Removal of adhesive foreign bodies is also possible.

- Robotization is also possible.

- Compact and lightweight.