Cavitation Enhancement System

PERION-DB

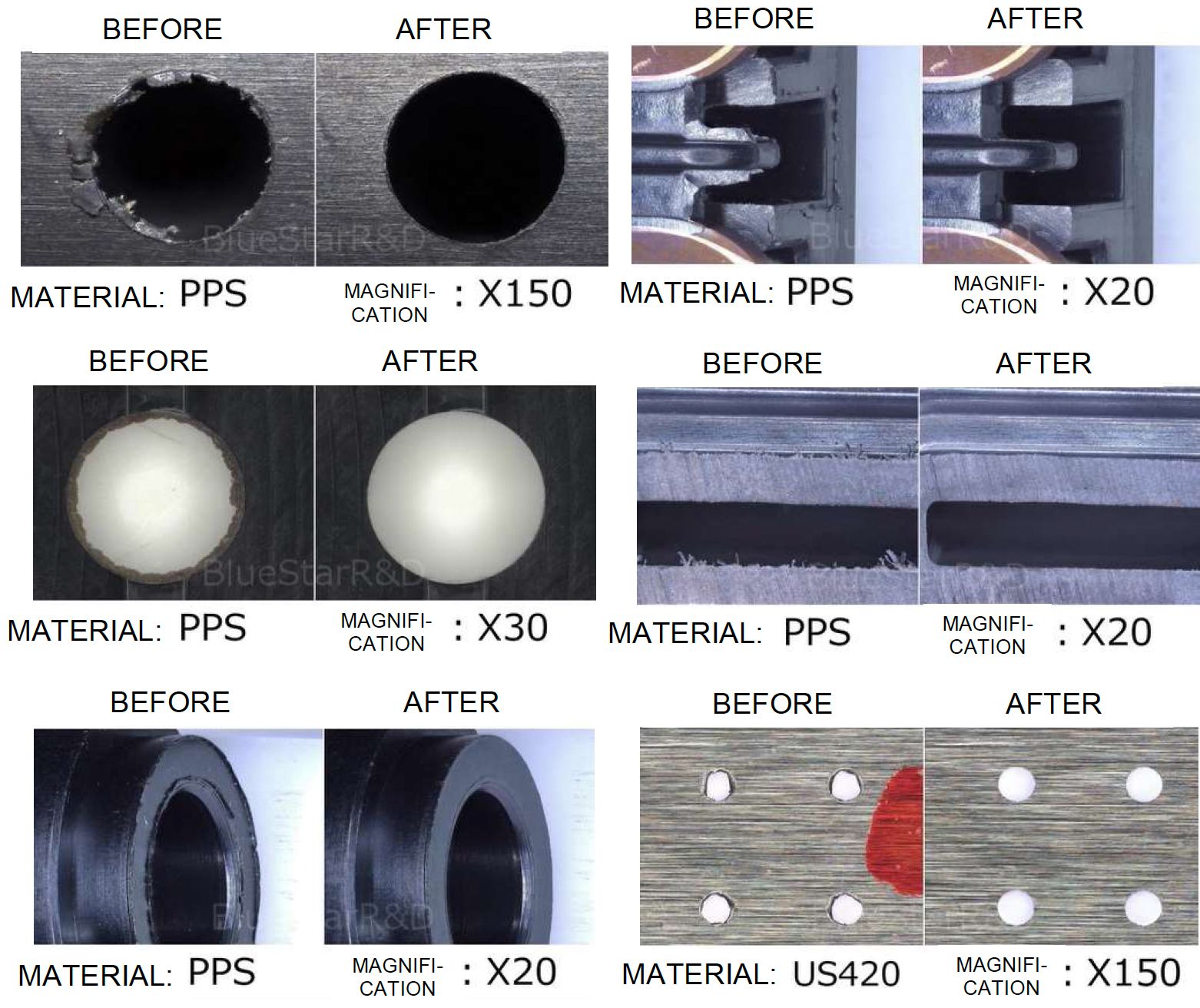

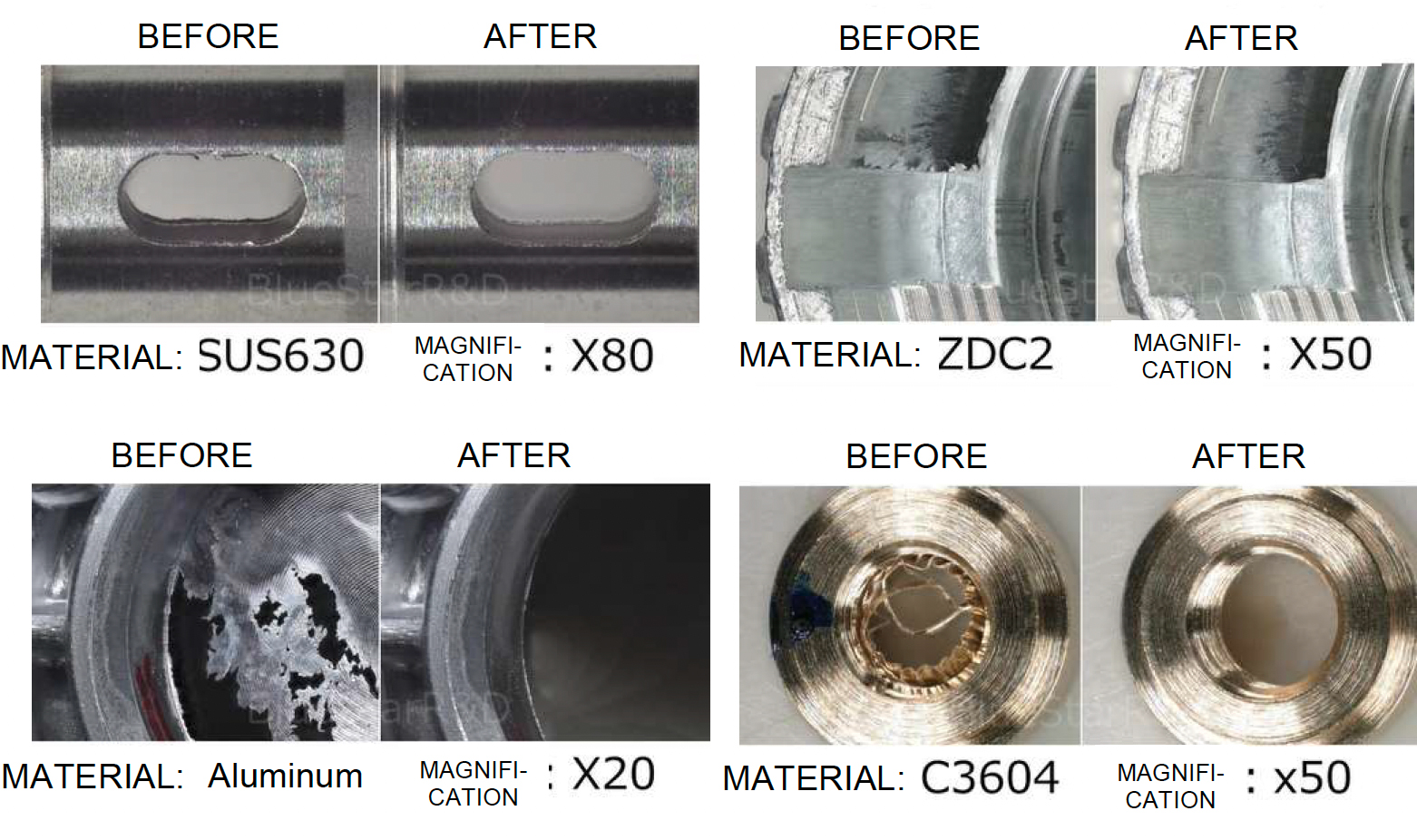

Our general-purpose, manually operated ultrasonic cleaning and deburring system features a Cavitation Enhancement System, along with a circulating filter and a vacuum degasser. By utilizing spherical nebula cavities, it delivers powerful ultrasonic cleaning and deburring capabilities. For delicate items such as semiconductor components and small electronic parts, selecting the appropriate oscillator frequency makes cleaning and deburring easier.

- Materials: Various metals, Plastics, Ceramics, and their compound materials

- Liquid usage: Pure water • City water

- Hydrocarbon solvent-type (Improved Explosion Resistance): DBU (Rust preventive agent or surface active agent are available), DBR (Hexagon rotating basket), DB-20 (20KHz very strong deburring system)