A Breakthrough in Power Improvement

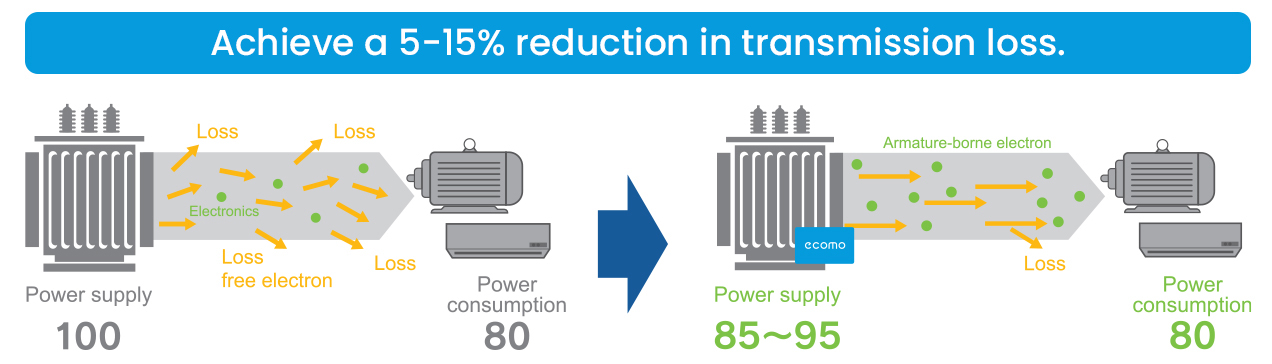

ECOMO is ushering in a new era of energy efficiency. This innovative device reduces power consumption by 5% to 15% for existing transformers and other equipment by leveraging natural materials such as tourmaline and ferrite, offering an eco-friendly and sustainable energy solution.

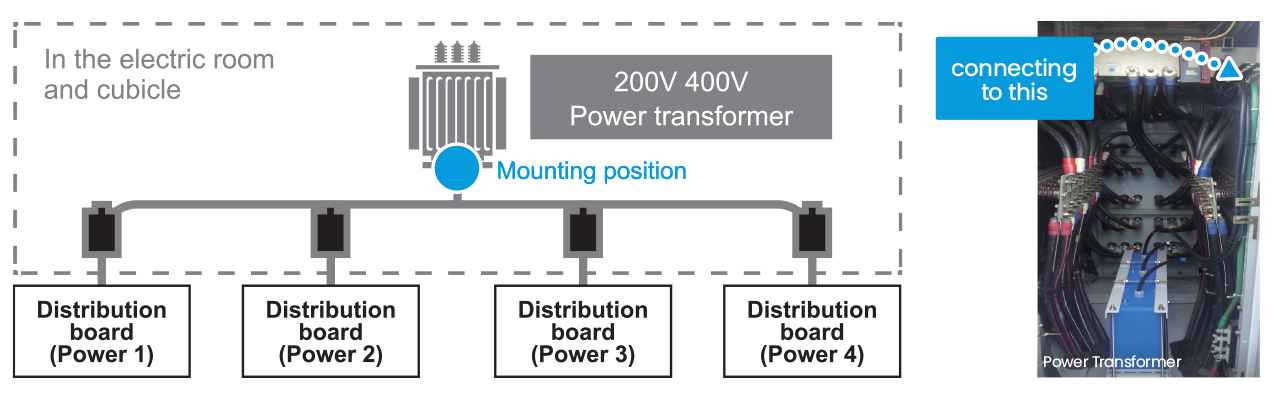

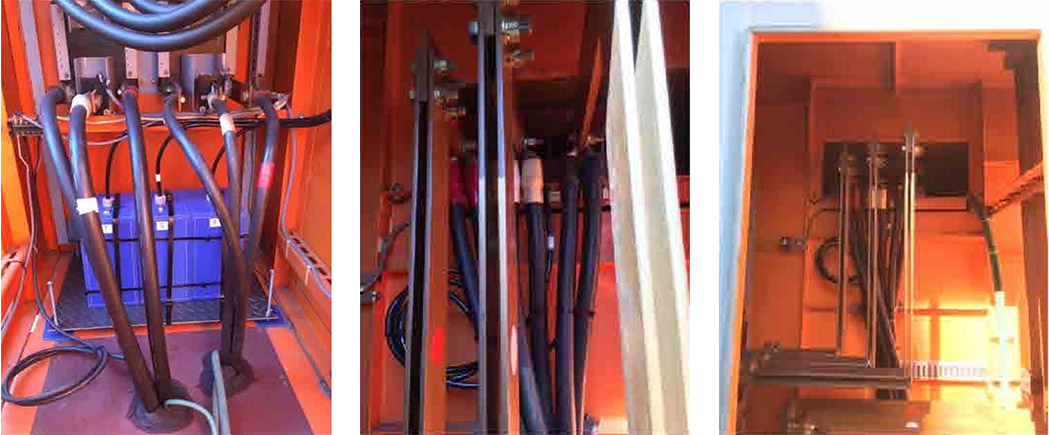

- Easy Installation: Installs in 30 to 60 minutes.

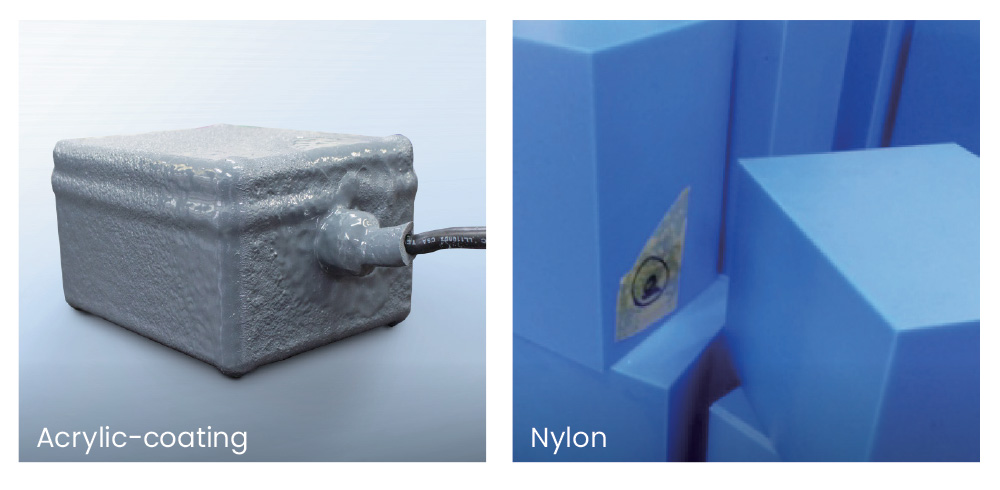

- Durable Design: Semi-permanent operation backed by a 7-year manufacturing warranty.

- Deployed in over 1,000 locations worldwide.